Industry in 3D, hosted by GE, showed off how additive manufacturing is on the cusp of redefining how some companies do business at every level.

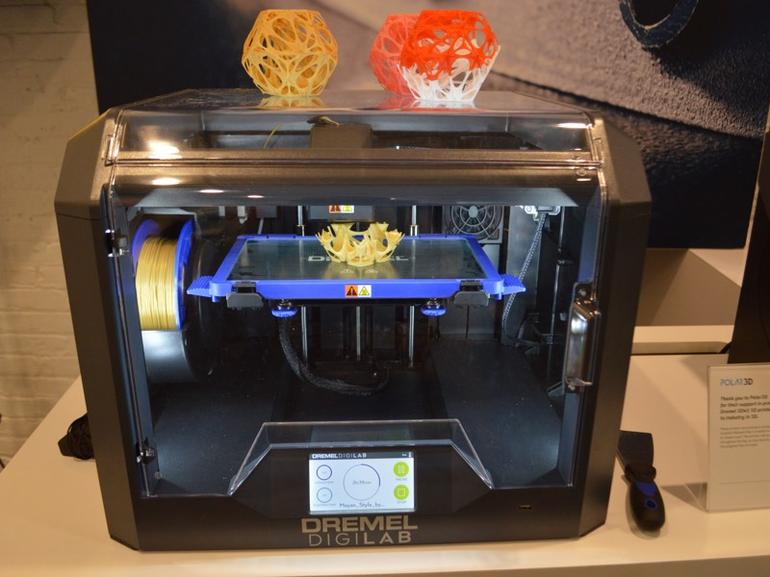

3D printing took over the headlines a few years ago as the next big craze, mesmerizing users with a visually stunning creation process. But while its popularity with consumers has started to wane, companies have only started to embrace the technology and are already seeing ways it can drastically change their industries. According to Gartner, the global 3D printing market will be worth $17.7 billion by 2020.

At GE's inaugural "Industry in 3D" event in New York, the company, its partners, and even some of its competitors joined together to show the world how 3D printing, also known as additive manufacturing, is upending supply chains and forcing them to retrain engineers to think about production without the constraints of the normal manufacturing process.

"It's not about making the same thing differently," said John Flannery of GE. "It's about rethinking the entire process to create higher quality products."

Representatives from GE, Boeing, Bombardier, Launcher, Stryker, Adidas, GM, and BMW illustrated how 3D printing is being used to print highly specific, expertly-designed parts for airplanes, cars, and spaceships as well as joint replacements, dentures, bicycles, and much more.

Jason Oliver, president and CEO of GE Additive, stressed that 3D printing was not about replacing workers with robots, but about remaking the manufacturing process for a modern society.

"This is not about substitution. This is about redesigning processes and rethinking production lines," he said. "This is the digitalization of manufacturing. Right now, additive is used mainly for high value, low volume products like aircrafts and engines."

Over $13 billion was spent on 3D printing over the last four years, but GE estimates that $280 billion will be spent on it in the next 10 years. But Oliver said a number of industry leaders are only dipping their toes into the 3D printing pool, wary of trying to integrate something that may be disruptive to how manufacturing has been done for hundreds of years. Every industry, he said, should be looking into ways they can augment their manufacturing model to prepare it for the near future.

Here are the three industries kickstarting the 3D printing revolution,

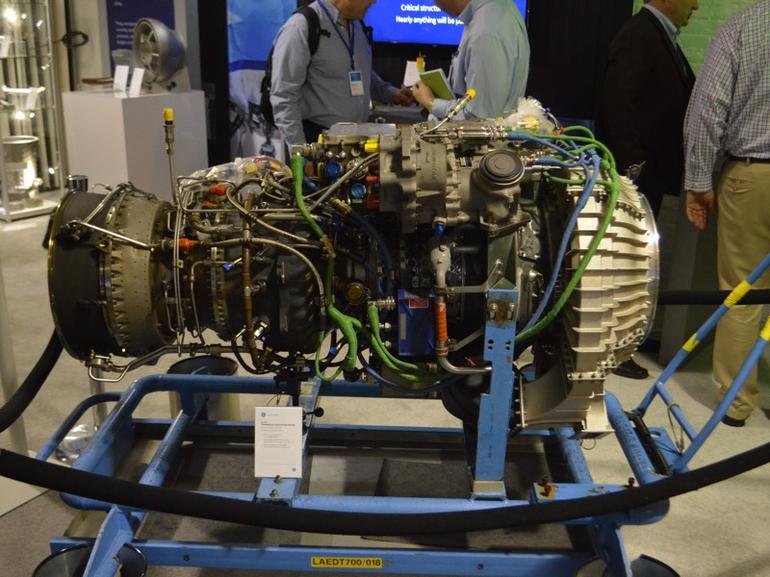

This helicopter engine is made of 40% 3D printed parts. Using additive technology, its creators were able to cut the weight down and increase the power of it. They also reduced the number of parts from 455 to 16.

1. Aviation/aerospace

Of all of the industries, the aviation industry is taking advantage of 3D printing the most, incorporating the technology in the creation of new, customizable parts that were arguably impossible to create before this.

Forty percent of a helicopter engine designed by a company using GE's 3D printing services was created with 3D printed parts and they were able to reduce the number of parts from 400 to 16. Another engine piece had been reduced from 855 parts to 12, which helped reduce the weight by 5 pounds and resulted in an 80% cost reduction. The ability to manufacture miniature parts that are specifically designed for each plane or spacecraft is changing what these modes of transport are capable of.

On the show floor, one company displayed a plane propeller that had been 3D printed and showed how the new process allowed them to monitor changes in the propeller over time. They could even be digitally notified of when the propeller had changed too much, something which previously required constant security and quality checks at a number of different levels. This is the concept of preventative maintenance so prevalent in Internet of Things (IoT) deployments.

Max Haut, founder and CEO of satellite company Launcher, said 3D printing was allowing them to compete with major companies and governments in a way that was impossible less than five years ago.

2. Healthcare

One of the most eye-opening parts of the event was the section on how 3D printing is affecting the medical industry. Some patients already have a number of 3D printed parts inside them, mostly knee and shoulder joint replacements, but the field is progressing rapidly by the year. Medical professionals are now able to make 3D printed parts that can mesh and grow with bone to create a more sturdy joint than before.

Specifically, the dental industry has taken 3D printing by the horns, adopting the process widely to create dentures and other mouth-specific designs that cannot be created en masse.

SEE: Photos: 3D printed dentures, bike, surgical tools, and more (TechRepublic)

Some companies are even hard at work on 3D printed organs, which is not as far away as one would think. A representative from Materialise, a 3D printed medical parts company, said they have already 3D printed a kidney.

Companies like Stryker are already pioneering new designs for casts and joint replacements and working with hospitals to widen the use of 3D printing. They have even designed a tool for doctors to suture wounds faster than ever before.

3. Energy

This drill bit is more durable and reliable than its regularly-manufactured counterparts and is used for gas and oil exploration.

GE is well known for its role in energy production across the world, and the firm is incorporating 3D printing into many stages of the production process. Drill bits that were previously costly and broke often are now 3D printed and tougher than ever, officials noted at the event.

For oil, gas, and renewable energy, GE and other companies are using 3D printing to cut down on the cost of materials and speed up production times. They are able to print replaceable parts on the spot instead of waiting weeks for new pieces, as noted at the event. Additionally, 3D printing with metals is used for both wind turbines and mining equipment, and is being adopted for more uses as we speak.

*this article was featured on the Tech Republic website on May 4, 2018: https://www.techrepublic.com/article/these-3-industries-are-kickstarting-the-3d-printing-revolution/